3D printed houses offer a unique alternative to conventional housing. They are cheaper to build, promise sustainability, and can be easily replicated.

However, one of their most promising features is the speed at which they can be built. Due to the highly automated nature of construction for these houses, they can be built completely in times that are many orders of magnitude lower than conventional houses.

So, how long does it take to build a 3D printed house? It takes an average of 30 hours to build a 3D-printed house. It ranges anywhere from a few hours to a month. The completion time depends on various factors. These variables include daily operation times, size of the house, complexity of the structure, and printing speed of the machinery among others. Even if it takes a full month to print a home, it is still much quicker than conventionally built houses that can take several years to reach completion.

Construction efficiency is a key factor in determining the final sticker price of a house. This includes time spent in labor and man-hours invested in the building process. 3D printed houses save costs in both of these categories. The laborious tasks are greatly cut back, and the automated nature of construction warrants a reduction in the number of man-hours needed on-site.

On a side note! If you’re looking for a reliable and high-quality 3D printer, we highly recommend the Official Creality Ender 3 V2 Upgraded 3D Printer (Amazon Link).

This printer is an upgraded version of the popular Ender 3 model, with a range of new features and improvements that make it even easier and more convenient to use.

Time is an important asset for construction companies and the less of it they have to spend per house, the cheaper they can sell it for (because the company will be able to construct more houses in the same amount of time).

- What are the factors that affect the speed at which a house is 3D printed?

- How do external factors affect the construction time?

- How long does the design process take for a 3D printed house?

- Does equipment matter?

- Do printer types affect the speed of construction?

- Examples of houses being 3D printed quickly

- What are the benefits of faster construction speeds?

- Conclusion

Now that we have established the need for and importance of faster construction, let’s take a deep dive into how that speed is achieved. We will take a look at multiple factors that play a role in making the 3D printing process faster and more efficient. We will also discuss the benefits of faster construction speeds (apart from money-saving, of course).

What are the factors that affect the speed at which a house is 3D printed?

There are many different factors at play that affect the speed at which a house can be 3D printed.

The first aspect to consider is logistics. Things like transportation, setup, preparation, and operation can all affect the efficiency (and hence printing time).

Transportation speed can be affected by how big the printing rig and its relevant parts are. Here modularity also plays a big role. Modularity can be understood as to how small the parts can be broken down. The smaller the parts, the easier they are to carry, load, and unload.

This saves time and makes transportation more convenient for the contractor. However, having a large number of parts might also cause more time to be spent in reassembling the rig. This could be a trade-off and a balance needs to be found between the two (smaller parts for easier transport and lesser parts for easier reassembly).

Ease of assembly and disassembly is also another important consideration. If the rig can be broken down and built back up using toolless hardware, then it will save a lot of time and make the transportation and setup process much more efficient.

The number of workers required for assembly can also affect the speed at which the setup can be put together. In sites where multiple rigs are being used together, worker availability can be a limiting factor in reducing the downtime between printing jobs. So, the lesser workers required for disassembly/reassembly, the more rigs can be worked on in a given time.

Lastly, when putting together the printing rig, the time needed for calibration, leveling, or other setup procedures can also influence the overall time required for construction. If the printing rig is automated, self-leveling, and self-calibrating then it can start printing soon after it has been set up, as opposed to a rig that requires manual leveling and calibration.

How do external factors affect the construction time?

Material transport and preparation is another factor to consider when setting up a printing rig for construction 3D printing. Due to the nature of printing, materials (most commonly concrete) require preparation and pre-mixing before they can be loaded into the printer.

The concrete (or other materials for that matter) being used in 3D printing need to have specific consistencies and specifications in order to be well suited for the 3D printing process.

It may entail curing, extra preparation steps, or the mixing of special additives (to alter the concrete’s characteristics). As you can guess by now, this can also add additional time to the overall printing process.

The amount of material being used is also an important consideration. Not only is it more environmentally conscious to use lesser materials, but it also contributes towards saving time. Lesser materials being used means that less time will be spent on transport, preparation, and curing and it will help cut down on the overall construction time.

Another important aspect that can be attributed to slowing down the printing (and hence overall construction) time is regulations. Being a novel concept, construction 3D printing is yet to be scrutinized by the building authorities of many countries.

Although there have been instances where housing authorities have approved 3D printed houses or where companies have made claims of following the building codes (source), these have been largely isolated events.

There is still a lack of comprehensive regulation regarding construction 3D printing and governments all over the globe are working towards making laws that regulate this sector of the construction industry.

Once the policy is implemented, following the code may end up leading to higher construction times.

Reading about record construction times may sound very pleasing, but in reality, most of these are just publicity stunts for companies to show off their potential. That is not a bad thing per se but for commercial applications, there is a whole host of other factors that need to be considered such as durability, longevity, and safety.

If you are curious about the durability of a 3D printed house, then click on this article for a more in-depth analysis.

Even though faster construction times are a lucrative feature for developers (because it saves them money), not to mention a great eye candy as well, it is important that certain aspects take precedence over speed.

If you are interested to learn more about the structural and fire safety of a 3D printed house, then check out this and this article, where both topics are covered.

How long does the design process take for a 3D printed house?

As you can well imagine, the design phase of a 3D printed house is also much different than a conventional one. The house needs to have a certain layout and shape for it to be “printable”.

This is because of the nature of additive manufacturing (the principle behind 3D printing). Only certain types of shapes are printable, and the houses need to be designed within those constraints. (For more on this, check out How Does 3D Printing Work? (Additive vs Subtractive Manufacturing))

The layering process also warrants some design modifications, and ultimately those can also affect the final layout of the house. For instance, building shapes that have no support beneath them is very challenging, as there are no layers below to support the weight of the layers above.

Architects and engineers need to take special care and take all these factors into consideration when designing the house. The advent of technology has made it so that these problems can be relegated to software and algorithms.

Programs like Solidworks and AutoCAD already offer extensions to their software which can be used as an aid in the design process. These programs can essentially work out the limitations of a specific printing rig and designers can use them to figure out which shapes are printable.

Does equipment matter?

Some rigs may also include automated hoppers that can mix the concrete and transport it using vacuum pumps. For other rigs, this process may be manual and may require labor. The former will definitely be faster and more time-efficient.

There are certain limitations in each setup that end up determining the final printing speed. It could be the pump’s maximum output, or it could be the maximum holding capacity of the mixer.

Printheads and the degrees of freedom they offer could reduce the constraints. For instance, the axes on which a printhead can move or rotate can determine the number of ways in which it can deposit the material on the layer below.

One not-so-obvious piece of equipment that can impact the speed of printing is the computer connected to the printer. A 3D printer works in unison with many sensors that take measurements and record data (like proximity, speed, flow rate, temperature, humidity, etc.).

This data is then sent to a computer that processes it to work out the most suitable set of instructions for the printhead. The printhead then does the printing accordingly.

The limiting factor here is the speed at which the computer can process the data. This determines the time delay (also known as the “lag”) between the computer getting the information and the printhead moving after processing that information.

The quicker the processing is done, the shorter the lag and the faster the printhead can print. What makes this a bit complicated is that this processing needs to be done multiple times every second because the computer needs to churn out instructions constantly for the printhead to print correctly.

So, a faster computer will allow the printing process to be quicker and hence it will help reduce the printing time for the house.

The type of printer may also contribute to the speed at which a house can be 3D printed.

Do printer types affect the speed of construction?

In the construction 3D printing space currently, there are two main types of printers. Both types differ on the basis of how their printheads are mounted (and are able to move).

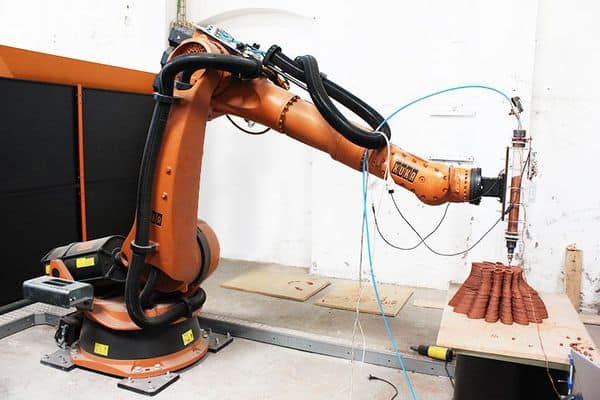

The first type uses a single robotic arm with multiple “joints” that allow the printhead to extend in all directions. Although it is less common, this type of printer has been successfully used by companies like Apis Cor in their projects.

Benefits of the robotic arm approach include its ability to print in multiple axes at various orientations. It essentially has higher degrees of freedom than other types of printers. This allows the printer to print complex and unique shapes that other printers would not be able to print.

The robotic arm printer is also relatively easier to transport and is more versatile in terms of placement and setup. It requires less space, and the arm can reach tighter spaces that other setups would not be able to. This saves time in transportation, site and equipment preparation, and setup.

However, the robotic arm isn’t without its shortcomings. Firstly, it is much less precise than a fixed printer. While on one hand the modularity and flexibility are advantageous to this type of printer, on the other hand, it causes it to be imprecise and inaccurate.

The robotic arm is also not able to cover a large footprint (in relative terms, compared to other printer types) and it needs to be moved and re-calibrated constantly throughout the printing process. One solution to this limitation is to have multiple printers working on the same project, but it is not the most logistically and economically feasible approach.

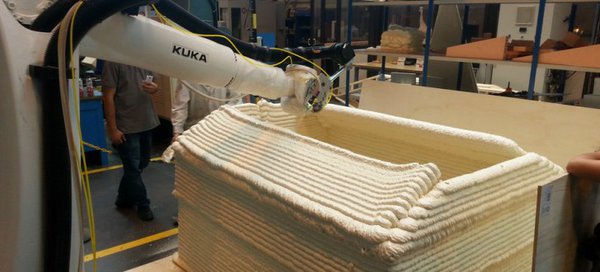

The second and more common type of 3D printer used in the construction space is the gantry-mounted one. This type of printer is used by developers that have large-scale, repeatable projects and is much more expensive than the first kind.

The major advantage of this type is that it can print much faster and cover a much larger footprint. The motorized gantries allow the printer to move in all 3 axes with a wide range of motion.

The nature of the setup also allows a much larger printhead to be mounted on the gantry which can have a higher flowrate of concrete and can also move faster through 3-dimensional space.

This setup also allows for easy replication of the same type of houses and structural elements. The printing is much more accurate, and the setup offers a higher degree of precision.

The most notable disadvantage of this approach is its lack of mobility. The gantries are large and bulky, and transporting them is difficult. The assembly and disassembly process is also challenging and it adds to the setup time.

The platform and work area for this type of printer also needs to be prepared (leveled, cleaned, and cordoned off) before the printing can begin. The printer also is not able to print certain shapes because its range of motion is limited in comparison to a robotic arm-mounted printer.

If the two types are compared on the basis of raw printing speed alone, then the gantry printer takes the lead. However, the gantry can take much longer to set up and preparation required prior to it can also add up to the total construction time.

On the other hand, the robotic arm printer can save time during the setup stage, but it lags when it comes to constant changes in positioning due to its limited reach.

It’s a game of balance whenever both approaches are employed. The advantages need to be weighed against the disadvantages, and considering the circumstances, the right approach needs to be selected.

However, with all things considered the gantry-mounted printer is still faster at printing when compared to the robotic arm. So, if you have a setup that does not require a lot of moving around and you need to print similarly styled houses quickly, then the gantry-mounted printer is the right choice for you.

It is important to mention here that these two are not the only two kinds of printers available. They are just the most common ones. Other approaches are being tested but have yet to see market-wide adoption and implementation.

One example of such an approach would be Smart Dynamic Casting (SDC) which is still in the early stages of development. The technology has a lot of promise, and it can allow the reinforcement to be incorporated into the 3D printing process, which traditionally has been difficult to do.

However, SDC as a technology is still in its infancy, so speed is not a huge concern for researchers at the moment. Hopefully, in the future technologies like SDC will be able to compete with other printing approaches in terms of speed as well.

If you want to learn more about SDC, you can check out this article for greater detail.

Examples of houses being 3D printed quickly

Around the globe, companies are competing for building the fastest homes. This race against time has resulted in some interesting examples of houses being built quickly. We will take a look at a few of them below.

Apis Cor (based in Florida) was one of the first companies to break the 24-hour mark when they completed a house just under that time back in 2017. This record has been beaten many times, but at that time it was a massive breakthrough in the construction industry.

WinSun, a company based in China, completed the impressive feat of building 10 houses in under 24 hours. These were built as part of a demonstration in which the company showcased its strengths, which included printing the world’s tallest 3D printed building as well.

If you want to read more about the tallest 3D printed building, check out this article.

WinSun also managed to construct a 12,000 sq. ft. luxury villa in just under 72 hours. The villa has three floors and it only required one gantry and 3 workers for the whole printing operation. It goes to show how efficient and effective the 3D printing process can be.

There have also been instances where groups of researchers have shown the potential capability of 3D printing rigs. At the University of Nantes, a shelter home was printed in just under 30 minutes to showcase the ability of 3D printers.

What are the benefits of faster construction speeds?

It is only logical to question the need for speed. There are certain scenarios and instances where speed can be useful.

In post-disaster situations, where people have been deprived of their homes and shelters, 3D printed houses can quickly be built to provide temporary refuge to these people.

Similarly, in instances where a lot of people are displaced from a region (due to crises or war), houses can be printed to provide shelter.

Faster construction speeds also save time and minimize disruption and disturbances. For instance, if a construction project was to be undertaken in a busy area, the roads would have to be cordoned off for many months, maybe even years.

However, if the project could be finished quickly, then the disruptions would only be temporary. This also applies to the duration for which the surrounding communities are affected. Their exposure to noise, dust and other forms of pollution would also be significantly reduced.

In addition, faster construction speed contributes to resolving the affordable housing issues, as discussed in Are 3D Printed Houses The Future Of Affordable Housing?

Conclusion

There are many aspects that contribute to making 3D printing faster and more efficient. The optimizations being carried out to achieve those speeds are modern marvels of engineering. Construction 3D printing still has a long way to go before it achieves widespread adaptability, but the potential is there just waiting to be realized.

It’s encouraging to see so many companies developing the technology at the same time. The difference in their approaches only shows how much room there is for innovation. I firmly believe that 3D printed houses are the future of construction and I cannot wait to see them being adopted all over the world.